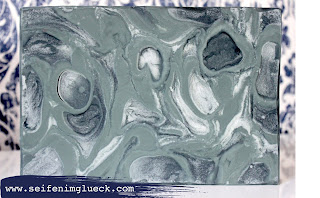

I'm quite delighted about the soap on the picture above that is colored with alkanet root powder. Therefore, I prepared an oil infusion (3 tablespoons of alkanet root powder in 10.5oz of olive oil), heated the jar in a water bath for two hours, let it sit for two month and shook it sometimes.

To prepare the soap, I divided the lye and the oils (36% coconut oil, 30% olive oil, 12% sweet almond oil, 8% avocado oil, 7% cocoa butter, 4% castor oil and 3% shea butter) in two parts and used different amounts of water to mix the lye. For the "high water soap" I used the amount of water that equals 2.4 times the weight of the sodium hydroxide (e.g. for 10 oz of sodium hydroxide: 10 oz x 2.4 = 24 oz of water) and for the "low water soap" I used the amount of water that equals 1.4 times the sodium hydroxide.

You can see the high water soap as dark purple colored parts of soap in the picture above and the low water soap as lighter colored parts. The amount of alkanet root powder as a percentage within the olive oil is identical. The color comes from the different amount of water in the lye solution.

The lighter colored soap (low water soap) modified its color during the curing time and the soap looks partly like a gradient soap now, I really enjoy this look!

The alkanet root powder colored soap, as well as the indigo colored soap that is shown below were both made within Amy Wardens soap challenge in February, experimenting with glycerin rivers while using high and low water soap.

The second soap (picture above) was also made with an oil infusion, this time I put about two tablespoons of indigo powder in 10.5 oz of olive oil. I put the infusion in a jar with a screw and heated the infusion in a water bath for two hours and waited for two months before using it and shaking the jar once in a while.

You can see also two colors within this soap: the dark colored soap contains water in its lye that equals 2.4 times the amount of its sodium hydroxide and the lighter part 1.4. The darker soap (high water soap) in the picture above carry a heavy amount of soda ash on its top and you can see this soap also made a sinkhole on the surface.

Various amounts of water within the lye (while having the same amounts of indigo or alkanet root powder in the oils) produced different colors. That occurred because the high water soap entered gel phase and gel phase helps the colors to occur more intense. The more water is used to mix the lye, the easier the soap enters gel phase.

On this second picture I plained the surface so you can see three different shades of indigo:

- dark indigo = high water soap that entered gel phase (looks like "lakes")

- light indigo not bright = low water soap that did not enter gel phase (limitations of the "lakes")

- light bright indigo = high water soap that did not enter gel phase (on the top of the picture in the middle, small "lakes")

Soap with a higher amount of water enters more easily gel phase that helps the colors to be more intense. The colors of the soap that didn't enter gel phase are not as intense. There are also parts of the high water soap that didn't enter gel phase. These are smaller "lakes" that didn't produce enough heat to enter gel phase.

The high water soap evaporated more water and therefore made a sinkhole. Surprisingly, this sinkhole was directly after the soap hardened and not (as you'd expect) after weeks of curing. Nevertheless, the planed soap produced another structure on the surface after 2-3 weeks of curing due to water evaporation.

Kevin Dunn did very interesting experiments in his book "Scientific Soapmaking" with high and low water soaps. Additionally he found out that it is save to use a 50:50 lye solution (same amount of water and lye to mix the lye solution) and that using too much water causes troubles. Also, Auntie Clara did stunning experiments using high and low water soaps, gained brand-new insights as well as did beautiful soaps with this technique, she named Ghost Swirl.

On the last picture you can see the whole block of indigo soap that I cut in 8 pieces of soap. The white "lakes" are soda ash on the high water soap. To avoid soda ash, water reduction is a good method, as you can see on the low water parts of the soap.

If you like to, I'd be glad to have a little discussion about this topic in the comments below :-)

Der Blog ist übersiedelt / this blog moved to:

www.seifenimglueck.com!

Ich freue mich auf deinen Besuch!

Alles Liebe, Diane

Keine Kommentare:

Kommentar veröffentlichen

seifenimglueck@gmx.at